- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

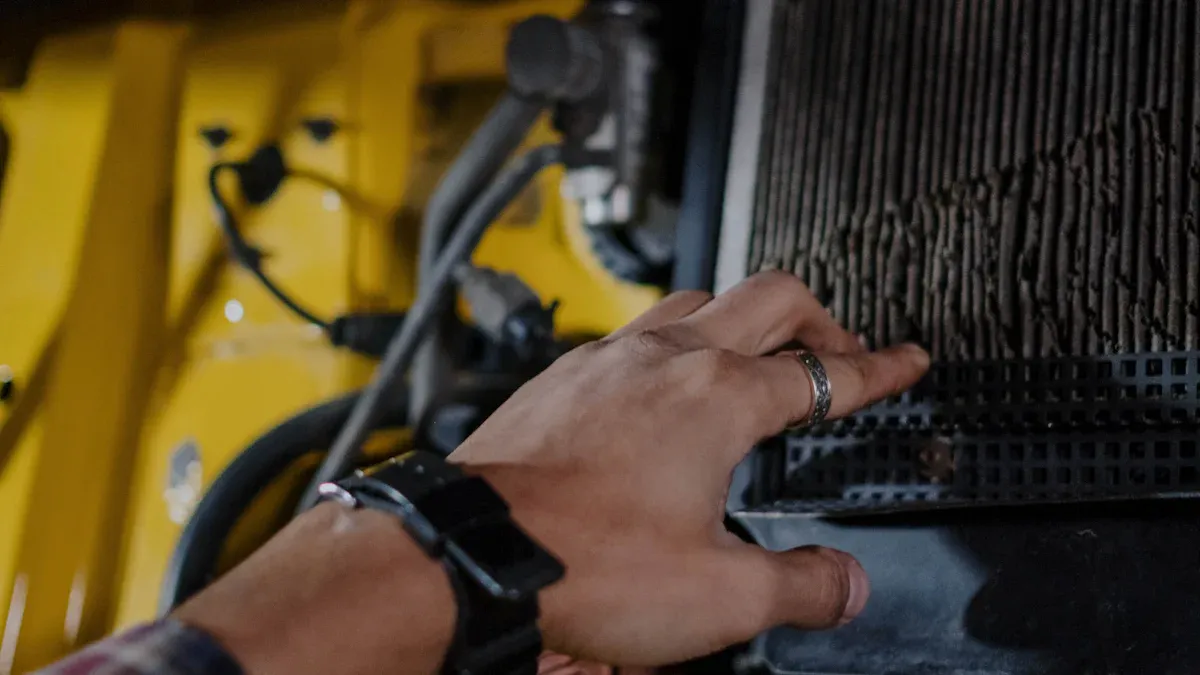

An air pre-cleaner sits within the air intake system of your engine. You use it to remove dirt, dust, and moisture before air reaches the main filter. This device works as the first line of defense for your engine, especially when you drive or operate equipment in harsh conditions. Many types of pre-cleaner exist, each designed to handle different levels of debris and airflow.

An air pre-cleaner removes large dust and debris before air reaches the main filter, protecting your engine from damage.

Using a two-stage air cleaning system with a pre-cleaner extends air filter life and reduces maintenance costs.

Centrifugal and cyclonic actions spin and separate dirt from the air, keeping filters cleaner and engines running better.

Air pre-cleaners help engines last longer by preventing harmful particles from causing wear and tear.

Installing an air pre-cleaner saves time and money by reducing filter changes and engine downtime in harsh environments.

You often hear about the air pre-cleaner when you look at the air intake system of an engine. This device sits before the air filter and acts as a first defense against dirt and debris. According to engineering sources, an engine air pre-cleaner is a device installed in the air intake system before the air filter. Its main job is to remove most of the dirt and debris from the air before it reaches the air filter. By doing this, the precleaner helps extend the life of the air filter and keeps harmful particles out of the engine. Most precleaners use centrifugal force to spin dust and debris away from the airflow. This process works well in heavy-duty and extreme environments, where engines face a lot of dust and dirt.

You can think of the air pre-cleaner as the first stage in a two-stage air cleaner system. The pre-cleaner removes larger particles, so the air filter can focus on trapping smaller ones. This setup improves the overall efficiency of the air cleaner and helps your engine breathe cleaner air.

Tip: Using a two-stage air cleaner with a precleaner can make your engine last longer and reduce maintenance costs.

When you look inside an engine's air intake system, you find several important parts that make the air pre-cleaner work. Here are the main components you might see:

Interior parts made of stainless steel, which resist dirt, water, and heat.

A rugged, one-piece aluminum hood with a special louver to keep out flying debris.

A stainless steel impeller, which is the only moving part and spins to create centrifugal force.

Separator vanes with special shapes to separate dust in very dusty places.

De-swirl vanes that straighten the airflow and reduce turbulence.

A serviceable inlet vane for easy cleaning.

Mounting brackets that let you adjust the position and rotation.

An ejection port that removes collected debris, either by itself or with a scavenge system.

Sealing surfaces with gaskets for sealed setups.

Flexible mounting options for different engine designs.

Some precleaners use stationary vanes and centrifugal force to spin dust outward, making the air cleaner even more effective. When you use a two-stage air cleaner, you get better protection for your engine, especially in tough conditions. The pre-cleaner keeps most of the dirt out, so the air filter does not clog as quickly. This means you spend less time and money on maintenance.

You want your engine to breathe clean air. The air pre-cleaner helps you achieve this by removing dust, dirt, and moisture before air reaches the main filter. When you look at how precleaners work, you see several designs, but most rely on physical forces to separate particles from the airflow.

Here is a simple breakdown of the main mechanisms:

Collection Bowl Precleaners

Air enters through angled vanes. These vanes spin the air, and centrifugal force pushes dirt and debris outward. The particles move along the inner wall and drop into a collection bowl. Clean air continues to the engine.

Aspirated Precleaners

These use centrifugal separation and a venturi effect. The venturi creates a vacuum that pulls contaminants away and ejects them into the atmosphere.

Atmosphere Discharge Precleaners

Incoming air passes through louvered openings. An impeller spins, using centrifugal force to separate dirt and moisture. The system expels these particles back into the atmosphere, while clean air enters the intake.

You find other types, such as foam-type precleaners and wet bath designs. Foam-type materials trap larger particles in their porous structure. Wet bath precleaners force air through a liquid medium, which captures dust and dirt. After separation, the system collects or expels contaminants, and only clean air reaches your engine.

Note: Most air pre-cleaners excel at removing particles larger than 0.65 micrometers. This means you get effective protection against coarse dust and debris, which can damage your engine.

You often see centrifugal and cyclonic action in modern air pre-cleaner designs. These methods use spinning motion to separate particles from the air. When air enters the precleaner, it spins rapidly inside a chamber. Centrifugal force pushes heavier particles outward, where they hit the chamber walls and fall into a collection bin or get expelled.

Cyclonic precleaners create a vortex. The swirling air forces dust and moisture to the outer edges. The system removes 80-90% of larger, heavier particles before the air reaches the main filter. This process keeps the filter cleaner for longer and reduces maintenance.

Traditional filters, like baghouses and cartridge filters, trap fine dust but struggle with sticky or fibrous particles. Cyclonic action solves this problem by removing troublesome debris before it reaches the filter. You get better performance, longer filter life, and less frequent cleaning.

Type of Action | What It Removes | Efficiency (%) | Best For |

|---|---|---|---|

Centrifugal | Large dust, moisture | 80-90 | Heavy-duty environments |

Cyclonic | Coarse, sticky particles | 80-90 | Wet or fibrous dust |

Foam-type | Larger debris | Varies | Light-duty use |

Wet bath | Dust, dirt | Varies | Extreme dust |

Tip: If you operate equipment in dusty, wet, or harsh conditions, a precleaner with cyclonic action can save you time and money by reducing filter changes.

You can see that the air pre-cleaner acts as a powerful first stage. It keeps most harmful particles out of your engine, so your air filter can focus on trapping the smallest dust. This combination gives you cleaner air, better engine protection, and longer-lasting equipment.

You want your engine to last as long as possible, especially when you work in harsh or dusty environments. An air pre-cleaner gives your engine a strong layer of protection. By removing up to 80% of dust and debris before the air reaches the air filter, you keep harmful particles out of the engine. This means you avoid premature wear on critical parts like pistons, valves, and turbochargers. When you use an air cleaner system with a pre-cleaner, you help prevent micro-abrasive dust from entering the engine. This reduces the risk of engine damage and keeps your equipment running smoothly.

Many air pre-cleaners use a "top-down" airflow design. This design spins and ejects dust before it can reach the engine. You get less engine wear, even in tough places like mines or construction sites. The table below shows how these features protect your engine and improve reliability:

Feature/Aspect | Description & Benefit |

|---|---|

"Top-Down" Airflow Design | Draws dirty air through a screen at the top, spinning and ejecting micro-abrasive dust before it reaches the engine |

Engine Protection | Prevents micro-abrasive dust and debris from entering the engine, prolonging engine life in harsh environments |

Efficiency & Power | Minimizes airflow restriction, maintaining engine breathing and maximum power in dusty conditions |

Durability | High-strength, corrosion-proof materials ensure reliability in tough environments |

Industry Testing | Tested to SAE J726 and ISO 5011 standards, confirming performance and reliability |

You can see that using an air cleaner with a pre-cleaner helps your engine maintain peak performance and reduces the chance of costly repairs.

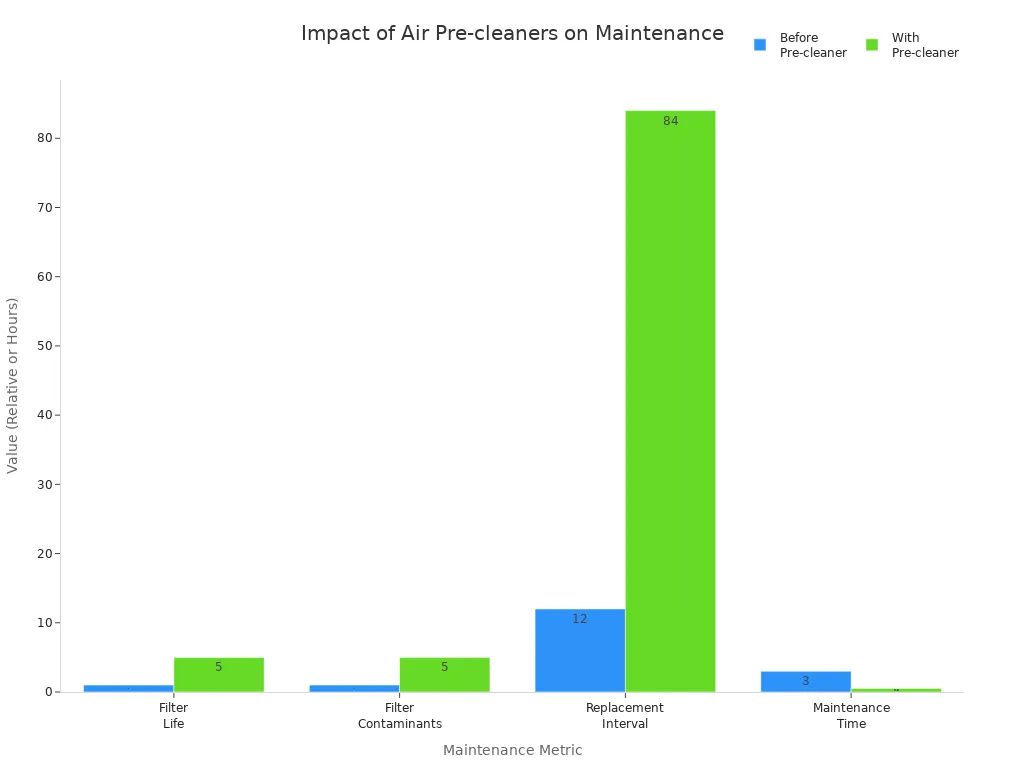

When you use an air pre-cleaner, you also extend the life of your air filter. The pre-cleaner removes most of the large particles, so the air filter does not clog as quickly. This means you spend less time and money replacing filters. In agricultural and construction equipment, air pre-cleaners have shown they can make air filters last 5 to 7 times longer. You save hours of maintenance each week and keep your machines working longer between service intervals.

The table below highlights the benefits you get from using an air pre-cleaner in your equipment:

Benefit/Metric | Description/Result |

|---|---|

Filter Life Extension | Air pre-cleaners extend filter life by 5 to 7 times |

Reduction in Filter Contaminants | 5x reduction in contaminants on filters |

Filter Replacement Interval | Increased from 12 hours to 84 hours |

Maintenance Time Saved | Saves 2–3 hours per day on filter cleaning |

Engine Wear Reduction | Reduces turbo and engine wear by preventing debris intake |

Operating Conditions | Effective in dusty, sandy, and residue-heavy environments |

Impact on Downtime and Costs | Less frequent cleanouts and replacements reduce downtime and maintenance costs |

By keeping your air filter cleaner, you help your engine maintain strong performance and reduce downtime. You also lower your operating costs and keep your equipment ready for work. Using an air cleaner system with a pre-cleaner is a smart way to protect your investment and boost engine performance.

You want your equipment to run smoothly with less time spent on repairs. An air pre-cleaner helps you achieve this goal by capturing dust, debris, and moisture before they reach the main filter. This early interception keeps the air filter cleaner for longer periods. You notice that filter life can extend from just 50-75 hours to over 500 engine hours. You also see filter change intervals increase up to 1,000 hours. These improvements mean you spend less time replacing filters and more time focusing on your work.

Air pre-cleaners remove up to 90% of contaminants before they reach the filter. This process reduces the risk of clogging and keeps your engine running at peak performance. You benefit from a self-cleaning design with sealed bearings, which lowers the need for frequent maintenance. Many users report a significant return on investment, sometimes saving up to $4,000 per engine due to reduced downtime and fewer filter replacements.

Tip: Easy clamp-on installation lets you add an air pre-cleaner without special tools, making upgrades simple and quick.

Here is a quick look at how air pre-cleaners help you save time and money:

Extended filter life up to 12 times

Fewer air filter changes

Less engine downtime

Lower maintenance costs

You often face tough conditions, such as dust, sand, or moisture. An air pre-cleaner gives your engine reliable protection in these environments. It filters out debris and particles as small as one micron, keeping airflow unrestricted for maximum engine performance. You see these devices used in mining, agriculture, construction, and snow removal equipment because they maintain strong performance even when the air is dirty.

The table below shows how air pre-cleaners support reliability and performance in harsh settings:

Benefit/Feature | Description |

|---|---|

Contaminant removal | Removes up to 80-90% of air contamination before reaching the filter |

Downtime reduction | Prevents filter clogging, prolongs engine and turbocharger life |

Application versatility | Works in earth moving, mining, agricultural, and stationary engines |

Warranty and trust | Backed by a 2-year warranty, trusted by OEMs and global equipment owners |

You keep your engine running longer and avoid costly breakdowns. Air pre-cleaners help you maintain high performance and reliability, no matter how challenging the environment.

You protect your engine and boost equipment performance when you use an air pre-cleaner. This device removes large dust particles, reduces engine wear, and extends filter life. Industry reports show that advanced models improve fuel efficiency and lower maintenance costs. Manufacturers recommend air pre-cleaners for tough jobs, noting longer service intervals and better uptime. As demand grows across industries, you see air pre-cleaners as a smart investment for durability and cost savings.

Choosing an air pre-cleaner helps you maintain engine reliability and meet industry standards for protection.

You use an air pre-cleaner to remove large dust and debris before air reaches the main filter. The air filter then traps smaller particles. Both work together to protect your engine and extend filter life.

You can install most air pre-cleaners on many engines, including trucks, tractors, and construction equipment. Always check your engine’s size and airflow needs before choosing an air pre cleaner or snorkel pre filter.

You should inspect your air pre-cleaner regularly, especially in dusty environments. Clean or empty the collection bowl as needed. Some air filter pre cleaner models require replacement after heavy use. Always follow the manufacturer’s instructions.

An air pre-cleaner helps your engine breathe cleaner air. You get better performance and less risk of clogging. Using a pre filter for air purifier or engine keeps airflow strong and reduces maintenance.

Yes! You find centrifugal, cyclonic, foam, and wet bath types. Each air pre cleaner works best in certain conditions. For example, a snorkel pre filter suits off-road vehicles, while a foam air filter pre cleaner fits light-duty use.