- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-24 Origin: Site

A 3 stage air compressor filter improves air quality by removing dust, oil, and moisture from the air you use in your operations. Clean compressed air keeps your equipment running smoothly and helps ensure high-quality end products. When contaminants enter your system, you may experience:

Equipment damage

Compromised product quality

Higher maintenance costs and shorter equipment lifespan

Using the right filter protects your investment and supports reliable performance.

A 3 stage air compressor filter removes dust, oil, and moisture, ensuring cleaner air for your operations.

Each filter stage targets specific contaminants, protecting your equipment and improving product quality.

Regular maintenance of filters is crucial; check them weekly and replace as needed to avoid costly downtime.

Using a multi-stage filter system can save space and reduce costs compared to separate filters for each contaminant.

Cleaner air output leads to longer equipment life and fewer repairs, enhancing overall efficiency.

A 3 stage air compressor filter uses a series of different filter elements to clean the air before it reaches your tools or equipment. Each stage targets a specific type of contaminant. You get better air quality because the filter removes particulates, oil, and moisture in steps. This process meets strict air purity standards. For example, many systems use a combination of molecular sieve, activated carbon, and hopcalite elements. The first stage removes most of the moisture from the air. The next stage targets oil and fine particles. The final stage eliminates any remaining trace moisture and vapors. This design ensures that the air you use is clean, dry, and safe for sensitive applications.

Tip: Multi-stage filtration saves space and can reduce costs compared to using separate filters for each contaminant.

Here is how multi-stage filtration compares to single-stage systems:

Filter Stage | Purpose of Removal |

|---|---|

Oil Separator Element | Removes bulk oil from the compression process |

General Purpose Coalescing Filter | Acts as a second line of defense for further cleaning |

High-Efficiency Coalescing Filter | Primary stage for oil aerosol removal |

Activated Carbon (Adsorption) Filter | Final stage for sensitive applications to remove oil vapor |

You need three stages in your air compressor filter to achieve the highest level of air treatment. Each stage works at peak efficiency to remove a specific group of contaminants. The first filter captures particulates like dust and dirt. The second filter removes oil and water droplets. The third filter targets vapors and odors that can affect your equipment or end product. This layered approach ensures that the air leaving your compressor meets the needs of even the most demanding applications.

You protect your equipment from damage caused by moisture and oil.

You extend the life of your compressor filters and reduce maintenance needs.

You improve the quality of your end products by using cleaner air.

A 3 stage air compressor filter system is essential for anyone who wants reliable air treatment and long-lasting equipment performance.

A 3 stage air compressor filter uses three distinct stages to remove a wide range of contaminants from the air. Each stage targets a specific type of impurity, ensuring that the air delivered to your equipment is as clean as possible. This process protects your tools, improves product quality, and extends the life of your compressor filters.

The first stage is the particulate filter. You rely on this filter to remove larger solids and moisture from the compressed air. It uses a 5 micron element to trap dust, rust, and other particulates that enter the system. This step prevents these contaminants from reaching sensitive downstream equipment.

Note: The particulate filter can remove up to 99.99999% of solid particles above 0.3 microns, depending on the filter media.

Micron Size | Filtration Efficiency (%) |

|---|---|

Above 0.3 | 90% to better than 99.99999% |

You benefit from this stage because it captures the majority of debris and moisture early in the process. This reduces the load on the next filters and helps maintain consistent air quality. Fine particulate filters are essential for applications that demand clean air, such as painting or food processing.

The second stage is the coalescing filter. This filter focuses on removing fine liquid aerosols and oil droplets that the first stage cannot catch. It uses densely packed fibrous media to intercept tiny oil mist particles and water droplets. As these small droplets pass through the filter, they merge into larger droplets. Gravity then pulls these larger droplets down, allowing them to drain away from the air stream.

Coalescing filters efficiently remove fine mist and aerosols.

The filter media causes tiny droplets to combine, making drainage easier.

This stage captures submicron particles and very fine aerosols.

Removal Rate | Description |

|---|---|

95% - 99% | Typical removal rate of oil and water aerosols by coalescing filters in industrial applications. |

0.01 microns | Efficiency against very small particles. |

You gain cleaner air output and protect your equipment from oil and water damage. This stage is especially important for industries that require high air purity, such as electronics or pharmaceutical manufacturing.

The third stage is the adsorption filter. This filter removes vapors and odors that can remain after the first two stages. It targets oil and hydrocarbon vapors, which are especially problematic in industries like food processing and instrumentation. The filter uses materials such as activated carbon, zeolites, or metal-organic frameworks to trap volatile organic compounds (VOCs) and other gases.

Material | Effectiveness |

|---|---|

Activated Carbon | High adsorption capacity for VOCs, but difficult desorption. |

Zeolites | High thermal stability and selective adsorption. |

Metal-Organic Frameworks | High-performance adsorbents for VOCs. |

You benefit from this stage because it ensures the air is free from odors and harmful vapors. This is crucial for applications where even trace amounts of contaminants can affect product quality or safety.

Tip: Using all three stages in your 3 stage air compressor filter system gives you the best protection for your equipment and the highest air quality for your operations.

Each stage in the filter system works together to remove particulates, liquids, and vapors. This layered approach ensures that your air compressor delivers clean, dry, and odor-free air, which is essential for both equipment longevity and product quality.

A 3 stage air compressor filter targets the most common contaminants found in compressed air systems. You need to remove these impurities to protect your equipment and ensure high-quality results. Each stage of the filter system focuses on a specific type of contaminant, making your air cleaner and safer for use.

You often find solid particles in compressed air, such as dust, dirt, and rust. These particulates can enter the system from the environment or from the compressor itself. The first stage of the filter traps these solids before they reach your tools or products. By removing particulates early, you prevent blockages and reduce wear on your equipment.

Note: Removing solids and dust helps maintain consistent air flow and reduces the risk of damage to sensitive components.

Solid particles

Dust

Rust

Moisture and oil are common in compressed air systems. The second stage of the filter uses a coalescing element to capture fine liquid aerosols and oil droplets. This process combines tiny droplets into larger ones, which then drain away from the air stream. The coalescing filter is essential for removing both particulate and aerosolized liquids, while the adsorber filter eliminates oil vapors and odors. This combination makes the three-stage system more effective than simpler filtration methods.

You benefit from this design because it keeps your air supply dry and free from oil, which protects your equipment and improves product quality.

Coalescing filters remove both particulate and aerosolized liquids.

Vapor removal filters eliminate gases, vapors, and odors.

Dry particulate filters only remove dry dust and particulates.

The final stage of the filter system focuses on vapors and odors. Activated carbon filters can trap vapors, chemical fumes, and odors down to .003 microns. You need this level of filtration for high-purity applications, such as food processing or electronics manufacturing. Proper placement of the activated carbon filter at the end of the system ensures optimal performance and prevents clogging.

Feature | Description |

|---|---|

Function | Traps vapors, gaseous contaminants, chemical fumes, and odors |

Material | Activated carbon, known for its micropores that increase surface area |

Application | Used in high-purity applications to remove trace gases and sub-micron particulates |

Tip: Always place the activated carbon filter last in your system to maximize its effectiveness and lifespan.

By using all three stages, you remove solids, liquids, and vapors from your compressed air. This approach gives you cleaner air and better protection for your equipment.

You want the best air quality for your operations. A 3 stage air compressor filter gives you that by removing particulates, oil, and moisture at every step. The filter starts with pre-filtration, which catches larger particles and contaminants. The next stage uses coalescing or adsorption to capture water and oil droplets, along with toxic gases. Fine filtration then eliminates tiny particles like dust and germs. This process ensures only clean air enters your system.

Pre-filtration removes large particulates.

Coalescing or adsorption captures water, oil, and harmful gases.

Fine filtration eliminates dust and germs.

Cleaner air output means you meet strict air treatment standards. Industries such as manufacturing and healthcare rely on this level of purity for better quality control. You also reduce risks linked to air purity, which is crucial for sensitive manufacturing processes. High-quality compressed air and gas filters help maintain product integrity, especially in petrochemical and food processing applications.

Your equipment needs protection from contaminants. The filter keeps oil, moisture, and particulates out of your compressor and tools. Clean air reduces strain on your system, improving efficiency and performance. You avoid breakdowns and lower repair expenses. Using oil-free compressors and proper filtration helps maintain product quality by keeping the air free from contaminants.

Clean air extends the lifespan of parts.

You experience fewer failures and less downtime.

Better air quality means uninterrupted production.

Cleaner compressed air also prevents blockages and wear, keeping your equipment in optimal condition. You save money by reducing maintenance costs and avoiding costly downtime.

Regular filter maintenance ensures optimal performance. You should check and clean air filters at least weekly. Replace air filters every 500 hours. For clean environments, change the filter kit every 3,000 hours or 12 months. Standard replacement intervals range from 1,500 to 2,000 hours.

Maintenance Task | Frequency |

|---|---|

Check and clean air filters | Minimum weekly |

Replace air filters | Every 500 hours |

Change filter kit | Every 3,000 hours or 12 months |

Replace air filters | Every 1500 to 2000 hours |

Monthly inspection and regular replacement prevent pressure drops. A 2 psi drop can cause a 1% loss in compressor horsepower efficiency. High-quality filters may cost more upfront, but they lower maintenance needs and improve system efficiency.

Tip: Regular maintenance of point-of-use and air-line filters keeps your system running smoothly and prevents costly downtime.

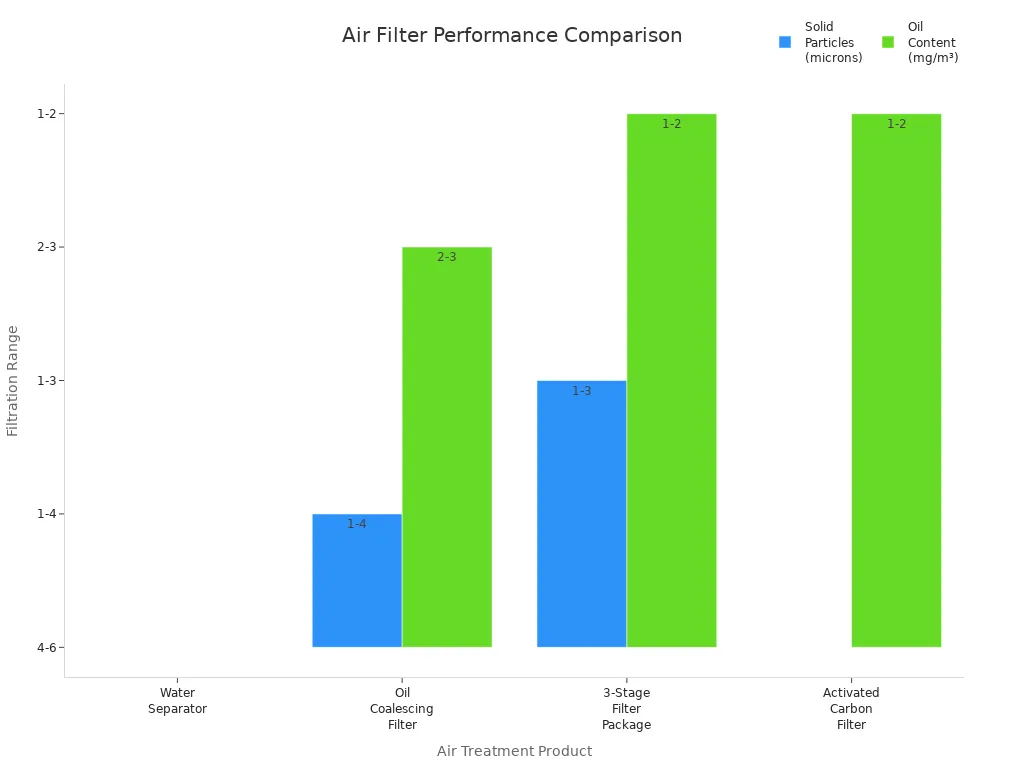

A 3 stage air compressor filter meets industry air treatment standards for solid particles and oil content. Properly matched filter solutions justify costs by increasing power output and protecting equipment.

You improve air quality and protect your equipment when you use a 3 stage air compressor filter. This system removes dust, oil, and moisture, giving you cleaner air for every application. Regular filter replacement keeps your compressor running efficiently and prevents pressure drops. Following a maintenance schedule helps your air compressor last longer and perform better. Future advancements will bring smarter, eco-friendly air filtration systems that use less energy and offer real-time monitoring.

Advancement Type | Description |

|---|---|

Smart Air Compressors | Real-time monitoring and predictive maintenance for better air quality |

Eco-Friendly Materials | Recyclable materials for sustainable air compressor filter technology |

Tip: Change your filters on schedule to avoid clogs and keep your air compressor working at its best.

A 3 stage air compressor filter removes dust, oil, and water from compressed air. You get cleaner air for your tools and products. This filter system protects your equipment and improves air quality.

You should check your air compressor filter system every week. Replace the air compressor filter for painting or other uses every 500 to 2,000 hours. Always follow the manufacturer's guidelines for air compressor filter replacement.

An air compressor filter water trap removes moisture from compressed air. You prevent rust and damage to your tools. This step is vital for any 3 stage air compressor filter system.

Yes, you can use a 3 stage air compressor filter for painting. This filter removes oil, dust, and water. You get smooth, clean finishes and avoid paint defects.

You get cleaner air, longer equipment life, and fewer repairs. The 3 stage air compressor filter system removes solids, liquids, and vapors. This system works well for many uses, including painting and sensitive manufacturing.