- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-14 Origin: Site

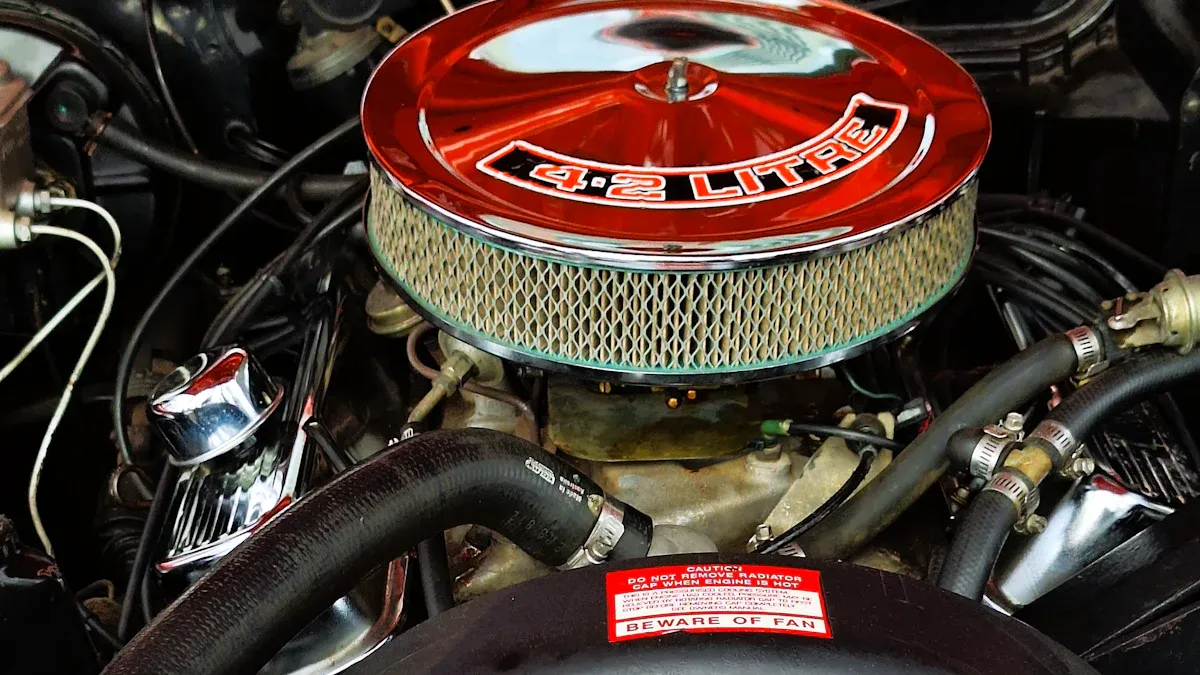

An oil-bath air filter removes dust and debris from incoming air by forcing it through a pool of oil. As air travels through the oil bath air cleaner, heavy particles drop into the oil, while smaller ones stick to the oil-soaked filter material. This process ensures cleaner air reaches your equipment. You often find these filters in settings where air quality matters most, such as:

Industrial sites

Manufacturing plants

Oil & gas refineries

Power generation units

Oil-bath air filters provide superior filtration by trapping both large and small particles, ensuring cleaner air for your equipment.

These filters last longer than paper filters, requiring less frequent replacement and saving you time and money.

Regular maintenance is essential; clean the filter every 3,000 to 5,000 miles to keep it effective, especially in dusty conditions.

Oil-bath filters are reusable, making them an environmentally friendly choice that reduces waste compared to disposable filters.

Choose oil-bath filters for harsh environments; they excel in dusty or humid conditions, protecting your engine effectively.

When you use an oil-bath air filter, you guide air through a two-stage cleaning process. First, air enters the filter and moves downward, sweeping across a pool of oil. This action causes the air to pick up a light mist of oil. As the air flows, it makes a sharp 90-degree turn. This sudden change in direction forces heavier dust and dirt particles out of the airflow. These particles drop into the oil, where they stay trapped. Next, the air passes through a steel mesh filter element. The mesh, coated with oil, captures smaller particles that escaped the first stage. This step ensures that even fine contaminants do not reach your engine or equipment.

Tip: The sharp bend in the airflow path uses inertia to separate particulates. This design helps the oil bath filter remove over 99% of airborne dust, making it highly effective in tough environments.

You will find several important components in an oil-bath air filter. The round base bowl holds the oil pool. Above the bowl sits an insert filled with filter media, such as fiber, mesh, or foam. The filter creates a winding path for air, forcing it to make U-turns. These turns help separate larger dust particles, which fall into the oil. The wetted filter media traps smaller particles as air continues through the system.

A built-in velocity stack plays a key role in filtration. This feature shapes the airflow, guiding it smoothly into the filter and helping maintain consistent air speed. The velocity stack, combined with the sharp bends in the airflow path, increases filtration efficiency. As dirt and oil build up, the oil bath filter actually becomes more effective, unlike traditional filters that may clog and lose performance.

Component | Function |

|---|---|

Oil Bowl | Holds oil to trap large particles |

Filter Media | Captures fine contaminants |

Velocity Stack | Directs airflow and boosts filtration |

You can rely on the oil-bath air filter to protect your equipment in dusty or harsh conditions. Its design ensures that both large and small particles stay out of your engine, keeping your machinery running smoothly.

When you consider the pros and cons of an oil-bath air filter, you notice several strong advantages. You get superior filtration because the oil traps both large and small particles. This design helps protect your engine or equipment in harsh environments. You benefit from high dust-holding capacity, which means the filter works well in places with lots of airborne dirt. If you operate in off-road or industrial settings, you will find that the oil-bath air filter lasts up to three times longer than paper filters. You do not need to replace it as often, which saves you time and money.

You also enjoy reusability. You can wash and reuse the filter instead of buying new ones every few months. The oil acts as a sticky trap for contaminants, so you get reliable protection. You help the environment by reducing waste, since you do not throw away filters as often. The open cotton material in oiled filters allows for greater airflow, which can improve performance in some applications. You may notice slight gains in power, especially if you use heavily modified or high-output engines.

Note: You should clean and check your oil-bath air filter every 3,000 to 5,000 miles. If you work in very dusty areas, inspect it more often. Change the oil at least once a year, or more frequently if conditions demand.

Advantages at a glance:

Superior filtration for both large and small particles

Excellent performance in dusty environments

Washable and reusable, leading to cost savings

Longer service life compared to paper filters

Slight performance gains in high-output applications

Sustainable choice with less waste

You must also weigh the cons when deciding if an oil-bath air filter fits your needs. Cleaning the filter takes time and effort. You need to remove the filter, wash it with a degreaser, rinse, dry, and re-oil it. The process can get messy, especially if oil spills or you lack the right tools. If you operate in dusty conditions, you need to clean and inspect the filter more often, which increases your workload.

Manufacturing costs for oil-bath air filters tend to be higher than for paper or foam filters. You may find that the filter does not allow as much airflow as some high-performance dry filters, which can limit engine power in racing or extreme applications. You must check for loose connections and proper oil viscosity before each use. Moisture can build up in the oil sump during rainy weather, so you need to clean it every one or two days to prevent engine problems.

Common Issues | Resolutions |

|---|---|

Need for regular cleaning | Check and clean the air cleaner every day under extremely bad conditions. |

Checking for looseness | Daily check of the shell-to-bottom shell connection pull hooks for looseness. |

Proper oil viscosity | Ensure machine oil is filled before operation, with viscosity similar to engine oil. |

Moisture accumulation | Remove and clean the oil sump every 1-2 days during moist or rainy conditions to prevent engine issues. |

Filter element replacement | Replace the lower filter element after three oil changes; replace upper and lower inlet cores after six oil changes. |

Tip: If you want less maintenance, you may prefer paper or foam filters for urban or low-dust environments.

Disadvantages to consider:

Labor-intensive cleaning and maintenance

Messy process with risk of oil spills

Higher manufacturing cost

Airflow limitations for high-performance engines

Frequent inspections needed in dusty or wet conditions

When you look at the pros and cons, you see that the oil-bath air filter works best in tough, dusty environments where durability and reusability matter most. If you value long-term savings and strong protection, this filter offers clear benefits. If you want less maintenance or maximum airflow, you may want to explore other options.

When you compare oil-bath air filters to paper filters, you notice some clear differences. Paper filters use a pleated material to trap dust and dirt. They are popular because you can replace them easily and they require almost no maintenance. You simply swap out the old filter for a new one when it gets dirty.

However, oil-bath air filters can match or even exceed the filtration efficiency of paper filters. Both types are efficient at filtering air, capturing over 99% of dirt particles when maintained properly. The main difference comes down to upkeep. You need to clean and re-oil an oil-bath filter, while you just replace a paper filter.

Filter Type | Average Upfront Cost |

|---|---|

Oil-bath Air Filter | $40 - $100+ |

Dry Air Filter | $10 - $40 |

Paper filters cost less at first, but you need to buy new ones often. Oil-bath air filters cost more up front, but you can reuse them for years, which saves money and reduces waste over time. If you want a filter that is not very efficient in harsh, dusty environments, paper filters may not be the best choice.

Foam filters use a thick, porous material to catch dirt. You often see them on motorcycles, ATVs, and small engines. Foam filters work well in dry, dusty places because they trap large amounts of debris. However, they can become very restrictive if they clog up with dirt.

Oil-bath air filters perform better in wet or humid conditions. The oil in these filters repels water and traps fine particles, making them ideal for moist environments. Foam filters may struggle in wet weather, as water can pass through the foam and reduce filtration. You should inspect and clean an oil-bath air filter every 10,000 to 15,000 miles, while foam filters may need more frequent attention in dusty areas.

You should choose your air filter based on your environment and maintenance preferences. Oil-bath air filters work best in harsh, dusty, or humid conditions. They last a long time and reduce waste, making them a smart choice for industrial or off-road use. Paper filters suit drivers who want easy, maintenance-free operation in cleaner environments. Foam filters fit well for small engines in dry, dusty places, but they may not protect as well in wet weather.

Tip: If you need a filter for long-term use in tough conditions, oil-bath air filters offer proven efficiency and durability.

Oil-bath air filters give you strong protection against dust and debris. You get a filter that lasts longer and needs less frequent replacement than paper filters. Here is a quick look at the main pros and cons:

Pros | Cons |

|---|---|

Self-cleaning capabilities | High airflow can cause oil bubbling, reducing effectiveness |

Filters fine dust very well | Potential clogging with prolonged high air flows |

Lower maintenance frequency |

You should choose an oil-bath air filter if you use heavy-duty, off-road, or vintage vehicles. Always match the filter to your equipment and prepare for regular cleaning and re-oiling. This choice keeps your engine safe in tough environments.

You should clean your Oil-bath Air Filter every 3,000 to 5,000 miles. If you work in dusty or wet conditions, inspect and clean it more often to keep your equipment safe.

You need to use machine oil with viscosity similar to engine oil. Avoid using cooking oil or other substitutes. Proper oil helps trap dust and protects your engine.

Heavy-duty vehicles, tractors, industrial machines, and off-road equipment benefit most. You get reliable filtration in harsh, dusty, or humid environments.

You may notice slight gains in power because the filter allows steady airflow. The main benefit is cleaner air, which helps your engine run smoothly and last longer.

You get longer service life and better filtration in tough conditions with an Oil-bath Air Filter. Paper filters need frequent replacement and work best in clean environments.