- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-01 Origin: Site

An oil-bath air filter protects your engine by trapping dust and debris before they reach sensitive parts. Air enters the filter, passes over an oil pool, and then moves through a steel mesh element coated with oil. This sticky layer captures particles, helping your engine run smoothly. Understanding this filtration method matters because it directly affects engine longevity and maintenance. Compared to modern air filter types, the oil bath air cleaner offers reusable benefits but requires more frequent care.

Oil-bath air filters let more fine dust through than paper filters.

Paper filters excel at fine particle removal.

Oil-bath filters improve at high engine speeds but allow more dirt into the oil.

Oil-bath air filters clean engine air by passing it over an oil pool and through an oil-coated steel mesh, trapping large and fine dust particles.

Regular cleaning and re-oiling keep the filter effective, especially in dusty or harsh environments, extending engine life.

These filters last longer and handle heavy dirt better than paper or foam filters but need more time and care to maintain.

Oil-bath filters work best in heavy equipment and farm engines where dust is common and engine protection is critical.

Modern vehicles mostly use paper or foam filters for convenience, but oil-bath filters offer strong, reusable protection in tough conditions.

When you look inside an oil-bath air filter, you see a unique design that uses both air movement and oil to clean the intake air. As air enters the filter, it does not travel in a straight line. Instead, the air flows downward and sweeps across the surface of an oil pool. This movement causes the air to pick up a light mist of oil. The air then makes a sharp 90-degree turn. This sudden change in direction forces heavier dust and dirt particles to separate from the airflow. These large particles fall into the oil, where they stay trapped. The oil surface also creates small waves and foam as air hits it, which helps capture even more dust and impurities. This first stage of the oil bath air cleaner removes most of the large, heavy contaminants before the air moves on to the next step.

After the air leaves the oil pool, it passes through a steel mesh filter element. This part of the oil bath air cleaner plays a key role in trapping fine particles that the oil pool did not catch. The mesh is made from strong materials like stainless steel or other metals. The design uses a woven or sintered wire mesh, which can have openings as small as 10 microns. The mesh holds a thin layer of oil on its surface. As the air flows through, any remaining dust sticks to the oil-coated wires. The table below shows some important details about the steel mesh filter element:

Aspect | Details |

|---|---|

Role in trapping fine particles | Captures small contaminants on the mesh surface; works like a woven cloth with micron ratings from 10 to 300 microns; keeps airflow resistance low and filtration efficiency high. |

Material specifications | Stainless steel (304, 316, 316L), carbon steel, galvanized steel, titanium, Inconel, nickel, Monel, Hastelloy; strong enough for high pressure and temperature; resists corrosion. |

Applications | Used in air, liquid, and gas filtration for industrial and engine systems. |

This steel mesh filter ensures that even fine dust does not reach your engine, helping to protect it from wear.

The oil bath filter uses a two-stage process to clean the air. First, the oil pool captures large particles by making the air turn sharply and pass over the oil. Next, the steel mesh filter element traps smaller particles with its oil-coated wires. This combination gives the oil-bath air filter its unique cleaning power.

You might wonder how well this system works. Laboratory tests, such as those following the ISO 5011 standard, measure how much dust and dirt the filter removes. These tests include oil carry-over, total life efficiency, capacity, and recovery tests. They help show how effective the oil bath air cleaner is at protecting your engine. The results prove that this type of air filter can handle tough, dusty environments, especially when you keep it clean and filled with fresh oil.

Tip: Regular maintenance of your oil-bath air filter ensures it keeps removing harmful particles and extends your engine’s life.

You need to clean your oil-bath air filter regularly to keep your engine safe. Cleaning helps remove trapped dust and keeps airflow strong. Follow these steps for proper maintenance:

Remove the air filter assembly from your engine. Disconnect hoses and loosen clamps.

Drain the old oil from the filter cup. Dispose of it safely.

Take apart the housing and remove the steel mesh or stuffing element.

Wash the cup and mesh with a solvent. Rinse them well.

Dry the mesh completely. You can use low-pressure air to speed up drying.

Inspect the filter for damage, rust, or holes. Replace any worn gaskets or seals.

Lightly re-oil the mesh with fresh oil. Avoid using too much oil.

Reassemble the filter and make sure all parts fit tightly.

Fill the oil cup to the marked level with clean oil.

Check hoses and fittings for leaks before reinstalling.

Manufacturers recommend cleaning the air filter at intervals based on your driving conditions. If you drive on highways, you may clean it every 15,000 to 25,000 miles. In dusty or harsh environments, you should clean it every 3,000 to 5,000 miles. On farms or during heavy use, daily cleaning was common to maintain filter efficiency.

Tip: Inspect your filter at every oil change. If the mesh looks dark or matted, clean it right away.

Oil bath filters need fresh oil to trap dust. Replace the oil based on how and where you drive. Severe conditions, like off-road or dusty roads, require oil changes every 3,000 to 5,000 miles. For normal driving, you can wait up to 25,000 miles. Always check the oil during regular maintenance. If the oil looks dirty or thick, replace it immediately. Using the correct oil weight helps the filter work well in different temperatures.

You may face some problems with oil-bath air filters. Cold weather can cause the oil to thicken or freeze, especially if moisture collects in the sump. This can stop your engine from starting. Use multi-weight synthetic oils to help prevent thickening in cold climates. The filter is bulky and can retain heat, which may affect engine performance. Regular oil changes and inspections help avoid these issues and keep your air filter working well.

You will find that modern engines usually use paper or foam filters instead of an oil bath air cleaner. Paper filters are lightweight and disposable. They trap fine dust and dirt with a dense, pleated material. Foam filters use a spongy material that you must oil before use. Both types offer easy installation and quick replacement. Here is how their maintenance and lifespan compare:

Oil-bath air filters require a detailed cleaning process. You must degrease, rinse, dry, and re-oil the filter. This takes more time than simply replacing a paper filter.

Foam filters also need cleaning and oiling, but you will do this more often in dusty conditions. They do not last as long as oil-bath filters.

Oil-bath filters can last the life of your vehicle if you maintain them well. Paper filters need regular replacement.

Note: If you want a filter that lasts, oil-bath types offer long-term value, but you must commit to regular maintenance.

Each filter type has strengths and weaknesses. Oil-bath air cleaners remove over 99% of dust and do not clog easily. They work well in harsh, dusty environments and save money over time because you reuse them. However, they are large and need frequent attention. Cold weather can make the oil thick, which affects performance.

Modern paper filters are small, light, and easy to change. They fit well in tight engine spaces and need little care. The downside is that they clog faster and must be replaced often, which adds to your costs. Foam filters fall between these two options, offering moderate maintenance and lifespan.

Filter Type | Advantages | Drawbacks |

|---|---|---|

Oil-bath | High dust removal, reusable, cost-effective | Bulky, needs maintenance, oil issues in cold |

Paper | Easy to replace, fits modern engines | Short lifespan, ongoing replacement cost |

Foam | Moderate care, flexible use | Needs frequent cleaning, shorter lifespan |

You will still see oil-bath air filters in heavy equipment, farm engines, and trucks that work in very dusty places. These filters handle large amounts of dirt without clogging, which is important for machines that run for hours in tough conditions. Modern vehicles use paper or foam filters because they are smaller and easier to maintain. However, if you work in agriculture or construction, the oil bath air cleaner remains a smart choice. Its ability to trap dust and last for years makes it valuable where reliability matters most.

You now understand how oil-bath air filters protect engines by forcing air over an oil pool and through an oiled mesh, trapping both large and fine particles.

You must clean and re-oil the filter regularly to keep it effective, especially in dusty environments.

These filters last longer and work well where dust is a problem, but they need more care than modern paper types.

You will still find them in heavy equipment and places where engine protection and uptime matter most.

You should check your oil-bath air filter at every oil change. Clean it every 3,000 to 5,000 miles in dusty areas. For normal roads, clean it every 15,000 to 25,000 miles.

Use engine oil with the same viscosity as your engine’s recommended oil. Multi-weight synthetic oils help prevent thickening in cold weather.

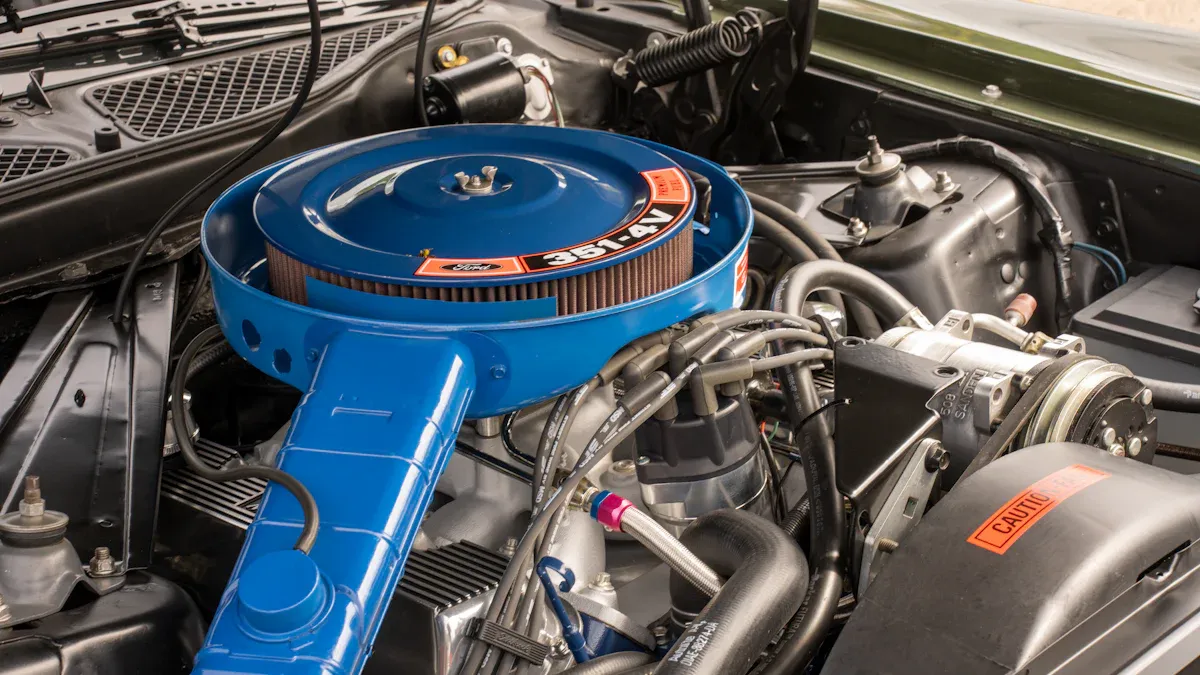

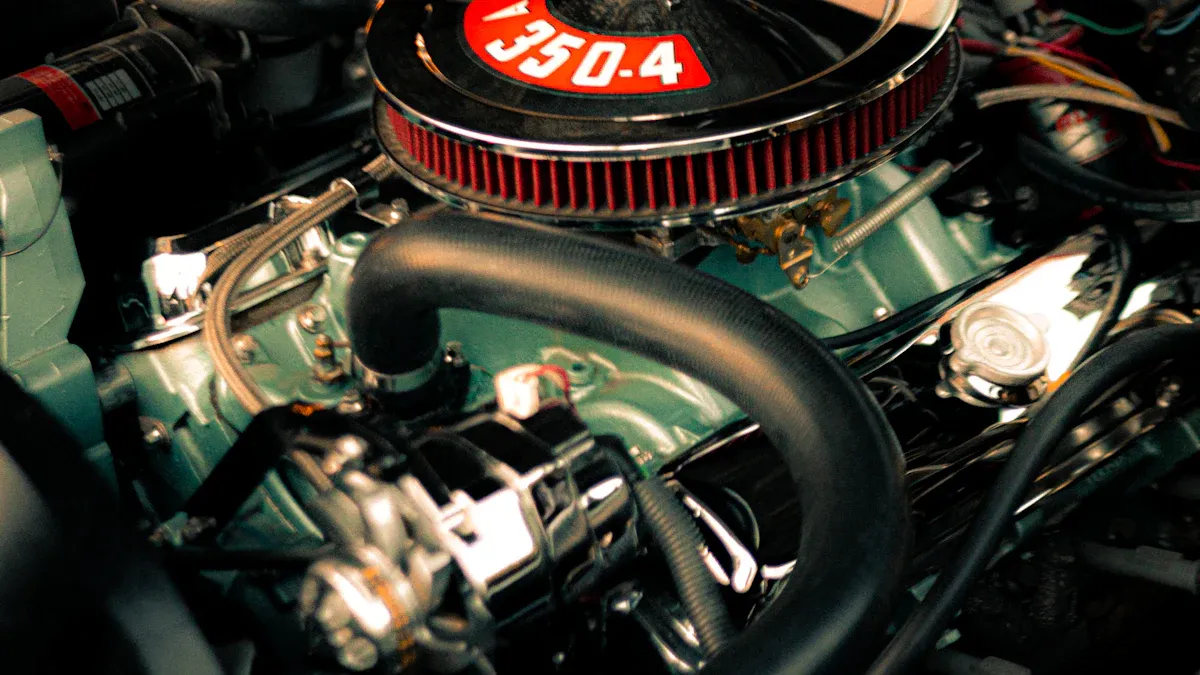

Most modern vehicles use paper or foam filters. You can use an oil-bath air filter in heavy equipment or classic cars, but it may not fit newer engine designs.

Look for dirty or thick oil, reduced engine power, or visible dust on the mesh. If you see leaks or damage, service the filter right away.

Oil-bath air filters work well in dusty or harsh environments. They last longer and handle heavy dirt loads, making them ideal for farm equipment and construction machinery.