- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-18 Origin: Site

You gain strong protection for your engine when you use an air pre-cleaner. This device removes over 80% of large dirt, dust, and water droplets from the air before it reaches your air filter. Cleaner air means less abrasive wear, longer filter life, and better engine efficiency. You see fewer breakdowns and lower maintenance costs because fewer contaminants reach sensitive engine parts. Regular cleaning and early issue detection help keep machinery running smoothly.

Air pre-cleaners remove most large dirt, dust, and water droplets before air reaches the main filter, protecting your engine and extending filter life.

They use spinning air and centrifugal force to separate heavy particles, reducing engine wear and improving performance.

Pre-cleaners lower maintenance costs and downtime by keeping filters cleaner and engines running smoothly in dusty or harsh environments.

Regular inspection and cleaning of your air pre-cleaner help maintain its effectiveness and prevent engine problems.

Using an air pre-cleaner saves money, boosts engine life, and keeps your equipment working longer and more efficiently.

You rely on an air pre-cleaner to protect your engine’s air intake system. This device sits before the main air filter and acts as the first line of defense. The air pre-cleaner removes most of the dirt, dust, and water droplets from the air before they reach the air filter. You benefit from this because it extends the life of your air filter and keeps your engine running smoothly.

The air pre-cleaner works by spinning the incoming air inside the air intake system. Centrifugal force flings heavier particles and water droplets outward, separating them from the airflow. The cleaner air then passes through the air filter, which now faces less strain. This two-stage air cleaner setup means you get better protection and longer service intervals.

Tip: Using a two-stage air cleaner with a precleaner helps you avoid frequent filter changes and reduces engine wear.

You find air pre-cleaners in many industries where engines face harsh environments. Construction sites, farms, and factories all use these devices to keep engines and equipment safe from dust and debris. The table below shows common places where you see air pre-cleaners and why they matter:

Industry/Environment | Why Use an Air Pre-Cleaner? |

|---|---|

Construction sites | Protect air cleaner from clogging, handle dust, maintain airflow |

Manufacturing plants | Remove particulate matter, protect filters, keep air intake system efficient |

Chemical processing | Control hazardous emissions, comply with regulations, protect air filter |

Steel manufacturing | Remove airborne dust, protect equipment and two-stage air cleaner systems |

Food processing | Maintain clean air, control odors, meet health standards |

Agriculture | Handle crop dust, extend air filter life, keep engines reliable |

You see precleaners used wherever engines work in dusty or dirty conditions. The two-stage air cleaner system, with a pre-cleaner and main air filter, gives you the best chance to keep your equipment running longer and more efficiently.

You see the power of cyclonic action every time you use an air pre-cleaner. The process starts when air enters the air intake system and spins rapidly inside a cylindrical chamber. This spinning motion creates centrifugal force, which pushes heavier particles outward toward the chamber walls. These particles cannot follow the curved airflow because of their inertia. They collide with the walls and slide down to a collection bin, while cleaner air moves upward through the center and exits toward the air cleaner.

Cyclonic separation relies on the scientific principle of inertia. Objects want to move in a straight line, but the curved path inside the chamber forces them outward. The design uses a tangential inlet to make air swirl, and gravity helps pull separated debris down. You benefit from this process because it removes contaminants without using filters, reducing pressure drop and maintenance needs.

Tip: Cyclonic separators can remove up to 95% of particles that are 30 microns or larger before air reaches the main filter. This means less dust, dirt, and water droplets enter your engine.

Modern air pre-cleaners use several mechanisms to boost efficiency:

Vanes guide the airflow and increase spinning speed.

Impellers create strong centrifugal force for better separation.

Foam types trap moisture and some fine particles.

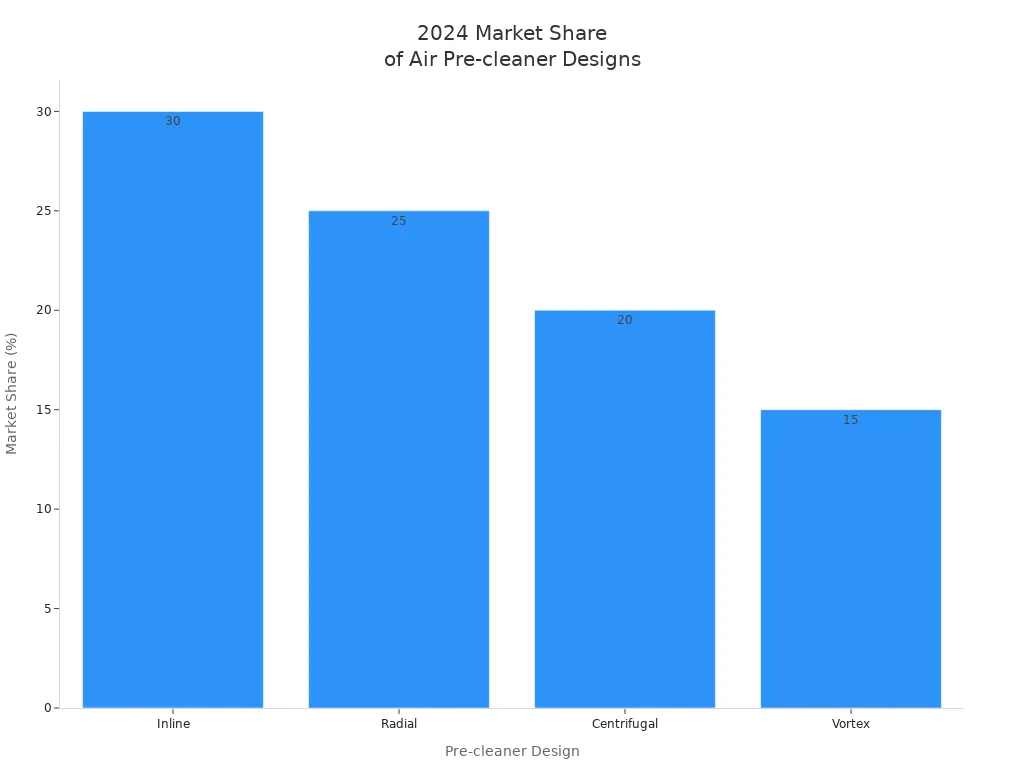

You find these designs in inline, radial, centrifugal, and vortex precleaners. Each type offers unique benefits for different environments. The chart below shows the market share of these designs in 2024:

You rely on an air cleaner to protect your engine from a wide range of contaminants. Air pre-cleaners target the largest and most damaging particles before they reach the main air cleaner. Here are the main types of contaminants removed:

Large fibrous debris such as chaff, cotton linters, and wood fibers

Heavy dust and dirt particles

Water droplets and moisture

Other airborne particles above 20 microns

Some precleaners can remove up to 94% of fibrous debris and 90% of heavy dust. You see these devices used in agricultural equipment, construction vehicles, and industrial machines. By spinning the air and separating contaminants, the air intake system stays cleaner and more efficient.

The table below compares different pre-cleaning methods and their effectiveness:

Method | Particle Size Range (µm) | Collection Efficiency (%) | Key Advantages | Key Drawbacks |

|---|---|---|---|---|

Conventional Cyclone | 2 - 10 | 60 - 80 | Low cost, low maintenance, low pressure drop | Less effective for fine particles (<5 µm) |

Wet Cyclonic Separator | 0.1 - 1 | >80 | Improved efficiency, lower cut-size diameter, lower water usage | Requires water injection, complexity in modeling droplet-particle interaction |

Wet Scrubber | 0.1 - 1 | >80 | High gas-cleaning capacity | High water consumption, high pressure drop |

You get the best results when you use an air pre-cleaner as the first stage in your air intake system. This setup extends the life of your main air cleaner and reduces engine wear. You also save money on maintenance and filter replacements.

Note: Enhanced cyclones with shunt devices can remove some fine particles below 1 micron, but most precleaners focus on larger contaminants.

If you want to understand how precleaners work, remember that the key is spinning air and using centrifugal force. This simple but effective method keeps your air intake system clean and your engine running smoothly.

You want your air filter to last as long as possible. Using a pre-cleaner helps you achieve this goal. The pre-cleaner sits before the main air filter and removes larger particles from the air. This process keeps the air filter cleaner for a longer time and reduces how often you need to replace it. You spend less money on filter replacements and keep your engine running with fewer interruptions.

Air pre-cleaners extend the lifespan of primary engine air filters by removing larger particles before they reach the main filter.

This process keeps the primary filter cleaner for a longer time, reducing the frequency of filter replacements.

Using air pre-cleaners lowers maintenance costs by protecting the engine from dust and debris.

They are especially beneficial in dusty or dirty environments to prevent premature engine wear.

The manufacturer emphasizes improved engine protection and sustained performance but does not provide specific lifespan extension figures.

Tip: If you work in construction, agriculture, or any dusty environment, you will notice that your air filter lasts much longer when you use a pre-cleaner.

You protect your engine when you use a pre-cleaner. The device stops micro-abrasive dust and dirt from reaching sensitive engine parts. Cleaner air means less friction and less damage inside your engine. You see better engine performance and longer engine life.

The TURBO® III PRECLEANER prevents micro-abrasive dust from entering heavy-duty engines, which significantly reduces engine wear and prolongs engine life.

Its patented 'top-down' airflow and 'stacked vane' technology create centrifugal force that separates dust and dirt from incoming air, ensuring cleaner air reaches the engine.

The design minimizes airflow restriction compared to competitor designs, helping maintain engine efficiency and reducing the need for frequent filter replacements.

The precleaner is tested to industry standards (SAE J726 and ISO 5011), demonstrating its reliability and effectiveness.

OEMs use this precleaner in the most demanding environments, confirming its proven performance in reducing engine wear and ensuring trouble-free service over years.

Cleaner air leads to better engine performance. You avoid costly repairs and keep your equipment working longer.

You save time and money when you use a pre-cleaner. The device keeps harmful debris out of your engine and prolongs air filter life. You spend less time on maintenance and more time using your equipment.

Prolongs air filter life, which reduces the frequency and cost of filter replacements.

Prevents harmful debris from entering the engine, lowering overall engine maintenance expenses.

Features a self-cleaning design that minimizes manual cleaning efforts.

Efficiently removes debris, thereby reducing equipment downtime and increasing productive work hours.

Built with durable, weather-resistant materials to ensure reliable performance in harsh environments.

Note: When you use a pre-cleaner, you increase productive hours and reduce the risk of unexpected breakdowns. You keep your equipment running smoothly and improve overall performance.

You benefit from cost savings and improved reliability. Your engine performs better, and you avoid unnecessary downtime.

You see air pre-cleaners at work every day in tough environments. On construction sites, machines like bulldozers and excavators face clouds of dust and debris. The Sy-Klone Series 9000 air pre-cleaner keeps these engines safe by blocking heavier-than-air particles before they reach the main air filter. This means your equipment runs longer, your air filter pre cleaner lasts more hours, and you spend less time on repairs.

In agriculture, tractors and harvesters often operate in high-dust fields. Tests on the CaseIH 580 Quadtrac tractor and Hitachi 690 excavator show how effective a pre filter for air purifier can be:

Aspect | CaseIH 580 Quadtrac Tractor | Hitachi 690 Excavator |

|---|---|---|

Environment | Agricultural, high-dust field conditions | Industrial, potash mining, dusty environment |

Performance Improvement | 5x reduction in filter contaminants | 7x increase in filter life (from 12 to 84 hrs) |

Maintenance Impact | Fewer filter cleanouts, consistent engine performance | Maintenance intervals extended from daily to weekly |

Cost/ROI Impact | Reduced downtime, improved productivity | Estimated $24,400 annual savings per machine |

You notice that using a snorkel pre filter or air pre cleaner in these settings leads to fewer breakdowns and lower costs. Your engine stays protected, and your equipment keeps working even in the harshest conditions.

You keep your air pre-cleaner working best with regular care. Follow these steps to maintain your air filter pre cleaner and avoid costly repairs:

Inspect the air pre-cleaner weekly for cracks, blockages, or wear. Increase checks if you work in dusty or harsh environments.

Clean the pre-cleaner by removing it and using compressed air to blow out dust and debris. Use a soft brush for stubborn dirt. Avoid water or harsh chemicals.

Replace worn seals, gaskets, or vacuator valves with genuine parts to prevent leaks and keep your pre filter for air purifier effective.

In severe conditions, check restriction indicators daily and service the snorkel pre filter more often.

After servicing, reset any indicators and record the maintenance for future reference.

Tip: Neglecting maintenance can lead to clogged air pre-cleaners, reduced engine power, and higher fuel use. Regular care ensures your air pre-cleaner protects your engine and extends the life of your air filter pre cleaner.

Common issues include cracked plastic bowls, clogged vacuum ports, and worn rubber valves. You avoid these problems by following a steady maintenance routine. Your air pre-cleaner will keep your engine safe and your equipment running strong.

You protect your engine and boost performance when you use an air pre-cleaner. This device removes up to 95% of dirt before it reaches the main filter, which means you see less engine wear and longer filter life. You also notice these key benefits:

Lower maintenance time and costs

Improved fuel efficiency and reduced emissions

Increased engine life and consistent performance

Consider adding an air pre-cleaner to your equipment. You save money and keep your machines running at their best.

You use an air pre-cleaner to remove large dirt, dust, and water droplets before air reaches your main filter. This protects your engine, extends air filter life, and keeps your equipment running smoothly.

You should inspect your air pre cleaner weekly. Clean it with compressed air or a soft brush when you see buildup. Replace it if you notice cracks, worn seals, or reduced performance.

Yes, you can combine an air pre-cleaner with a snorkel pre filter. This setup gives your engine extra protection in dusty or wet environments. You keep more contaminants out and improve engine reliability.

An air filter pre cleaner removes large debris, heavy dust, fibrous particles, and water droplets. You keep these harmful materials away from your engine and main air filter.

No, a pre filter for air purifier works in home or office air purifiers, while an air pre-cleaner protects engines. Both remove large particles, but you use them in different systems.