- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-09-18 Origin: Site

You rely on your air compressor filter intake to stop dust and dirt before they enter your machine. Tiny particles fill the air around you—up to 140 million per cubic meter—and most are smaller than 2 microns. This filter acts as your compressor’s shield, protecting it from harmful contaminants.

An air compressor intake filter protects your compressor by blocking dust, dirt, and harmful chemicals, ensuring only clean air enters.

Regularly inspect and clean your air filter to maintain performance and prevent costly repairs. Follow the manufacturer's guidelines for best results.

Replace your filter when you notice damage or reduced airflow. A clogged filter can lead to increased energy use and equipment failure.

You need an air compressor intake filter to keep your compressor running smoothly. This filter acts as the first barrier against dust, dirt, and chemical pollutants. According to industry standards, the air compressor intake filter blocks particles as small as 0.3 microns and removes harmful chemicals from the air. When you use a high-quality filter element, you ensure that only clean air enters your compressor. Clean air reduces wear on internal parts and lowers energy consumption.

Tip: Regularly check your air compressor filter intake to maintain compressed air performance and avoid costly repairs.

The intake filter also helps you maintain air quality. When you trap contaminants before they reach the compressor, you protect downstream filters like the lube filter and air-oil separator. This process leads to less contamination, less energy required, and better overall efficiency.

Your air compressor intake filter shields your compressor from a wide range of contaminants. Common threats include:

Particulate contaminants (dust particles, rust)

Moisture

Oil

Microbiological contaminants (bacteria, viruses)

Contaminants such as oil, dust, and moisture can damage your compressor. They reduce performance, harm air-powered equipment, and lower the quality of your end products. Dust and debris cause friction and wear, leading to premature failure. Moisture can rust tanks and pipes, clog control lines, and damage electrical systems.

Note: Keeping your air intake area clean and replacing the filter element regularly is vital for maintaining compressed air quality and compressor efficiency.

The air compressor intake filter serves as a physical barrier. It traps solid particles before they reach critical internal components, protecting them from wear and damage. If your filter gets clogged, you may face higher operational costs and reduced efficiency.

Here is a quick look at the types of filters used in different industries:

Filter Type | Purpose | Common Applications |

|---|---|---|

Particulate Filters | Remove dust, dirt, and rust | First stage filtration |

Coalescing Filters | Remove water and oil aerosols | Sensitive to moisture and oil |

Activated Carbon Filters | Remove chemical fumes and odors | High air purity needs (food, pharma, etc.) |

High-quality intake filters offer better protection and longer operational life than standard filters. They reduce maintenance needs and improve energy efficiency. Investing in advanced filtration systems may cost more upfront, but you save money in the long run by avoiding downtime and expensive repairs.

You can find several key parts inside a typical air compressor intake filter. Each part plays a role in trapping contaminants and protecting your compressor. The main components include:

Inlet: This is where compressor intake air enters the filter. An internal cap directs the airflow.

Filter cap: It guides the air and shows you the correct installation direction.

Air path: This is the route air takes as it moves through the filter.

Filter discharge: Clean air exits here, usually matching the inlet size.

Filter element: This part captures dust, dirt, and other contaminants.

Filter bowl: You see this part from the outside, attached to the cap.

Filter quiet zone: This area collects trapped contaminants so they do not re-enter the air.

Drain: This lets you remove collected debris and moisture.

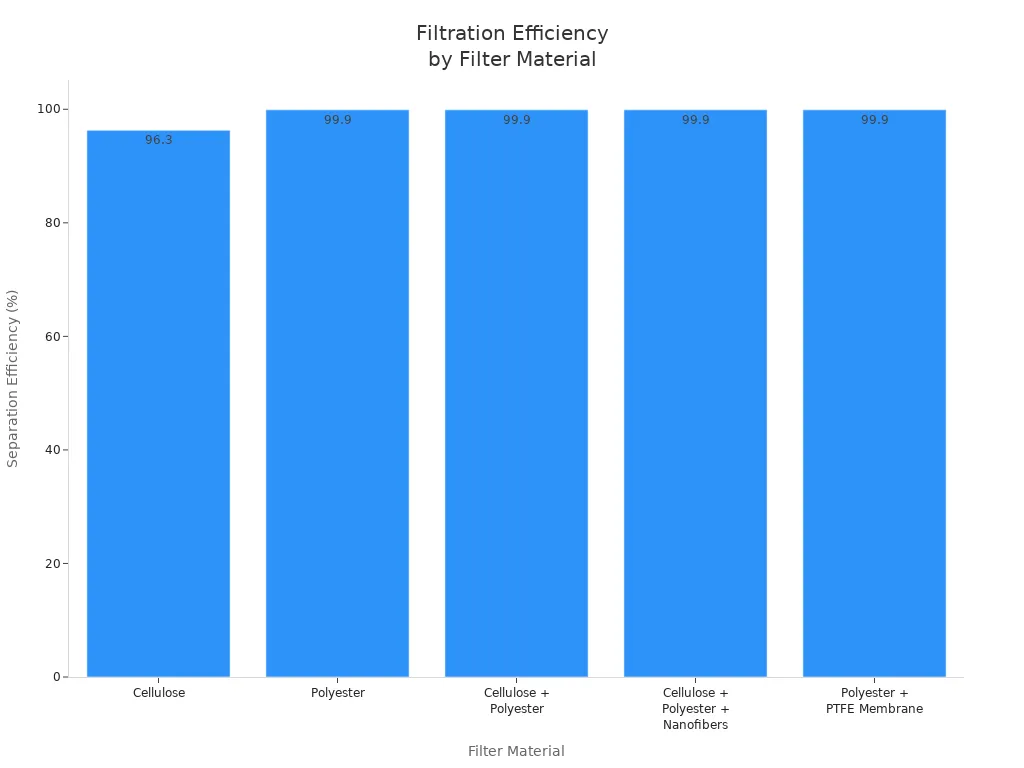

The filter element is the heart of the air compressor intake filter. The material used in the filter element affects the quality of filtration and overall compressed air performance. Here is a comparison of common filter materials:

Filter Element | Material Composition | Mass Loading (g/m2) | Max Dust Particle Size (µm) | Separation Efficiency (%) |

|---|---|---|---|---|

A | Cellulose | 31.9 | 28 | 96.3 |

B | Polyester | 5.77 | 7.9 | 99.9 |

C | Cellulose + Polyester | 48.5 | 10.3 | 99.9 |

D | Cellulose + Polyester + Nanofibers | 7.22 | 3.1 | 99.9 |

E | Polyester + PTFE Membrane | 5.77 | 7.9 | 99.9 |

The air compressor filter intake uses a step-by-step process to clean the air before it enters your compressor:

Mechanical Filtration: The filter element blocks large particles on its surface. Smaller particles get trapped deeper inside the filter media.

Coalescing Filtration: Fine fibers in the filter catch tiny liquid droplets. These droplets combine and fall to the bottom of the filter bowl.

Adsorption: Activated carbon granules in some filters attract and hold oil vapors and gases, improving air purity.

You get the best results when you use a high-quality air compressor filter. The right intake filter keeps your compressor running efficiently and extends its life by removing harmful contaminants from the air.

You keep your air compressor intake filter working efficiently by following a regular cleaning and inspection routine. Manufacturers recommend checking your air filter weekly to prevent clogging and maintain performance. You should always consult your manual for specific cleaning procedures and replacement intervals.

Here are best practices for cleaning and inspecting air intake filters:

Turn off and cool down your compressor before removing the filter.

Remove the filter housing and take out the filter element carefully.

Inspect the filter element for tears, cracks, or heavy buildup. Replace it if you see damage.

Clean dry particulate filters with low-pressure compressed air (under 30 PSI), blowing dust from the inside out.

Wash foam or washable intake filters with warm water and mild detergent. Let them air dry completely before reinstalling.

Clean the filter housing and intake vents to prevent dust accumulation.

Reinstall the filter element and test the system for normal airflow.

You should inspect the air compressor intake filter more often in dusty or humid environments. Relocating the intake to a cleaner area can also help improve air quality and reduce maintenance needs.

Tip: Regular cleaning and inspection prevent stubborn clogs, wear, and microfractures that weaken the filter element.

You need to replace your air compressor intake filter when you notice signs of wear or poor performance. Common indicators include visible damage, old filter elements, and a decline in compressor efficiency even after cleaning. Frequent use or operating in dusty areas means you should change filters more often.

A clogged intake filter restricts airflow, causing your compressor to overheat and work harder. This leads to increased energy consumption and potential damage to engine components. Maintaining clean air intake filters improves air quality, extends equipment life, and lowers environmental impact.

You should follow the manufacturer's recommended replacement intervals and monitor readings from any instrumentation installed in the suction line. Keeping air intake areas clean and replacing filter elements regularly ensures your air compressor filter intake delivers optimal performance and safety.

You depend on your air compressor intake filter to keep your compressor safe and your air clean. Neglecting regular maintenance can lead to:

Increased energy use

Equipment downtime

Expensive repairs

Poor product quality

Set a consistent schedule to inspect and replace your filter for reliable performance.

You should check your air compressor filter intake every month. Replace it if you see dirt, damage, or reduced airflow.

A clogged air compressor filter intake causes poor airflow. Your compressor works harder, uses more energy, and may break down sooner.

You can clean some air compressor filter intake elements. Foam and washable filters work best for reuse. Always follow your manufacturer’s instructions.